Biography

Haitham is a PhD student on a H2020 Marie Curie fellowship. Holding a master’s degree in Civil and architectural engineering. Specialized in sustainable construction, tool development, BIM, Life cycle assessment, and life cycle costing on building level. Has extensive experience in developing software mainly with python, including python backend webapps using the Django framework. Other experience includes working with Revit api using C#. Microcontroller software with C++, and linux.

- Life Cycle Assessments (LCA)

- Building Information Management (BIM)

- All things Python

- Linux

- AI and ML

- Micro-controllers

PhD in Environmental Economics, Ongoing

Hasselt University

MSc. Civil and Architectural Engineering, 2021

Aarhus University

BSc in Civil Engineering, 2017

Jordan University of Science and Technology

Skills

Experience

Topics include:

- Life Cycle Assessment

- Life Cycle Costing

- Sustainable Public Procurement

- Design for Disassembly

- AI in LCA

- Circular Economy

- LCA

- LCC

- SPP

- LCA

- LCC

- BIM

- Discovery based learning and gamification for sustainability education

- LCA

- Discovery based learning and gamification for sustainability education

- Structural Analysis

- Design

- Site Supervision

- Project Management

- Site Supervision

- Quality Control

Accomplishments

Projects

Featured Publications

Purpose

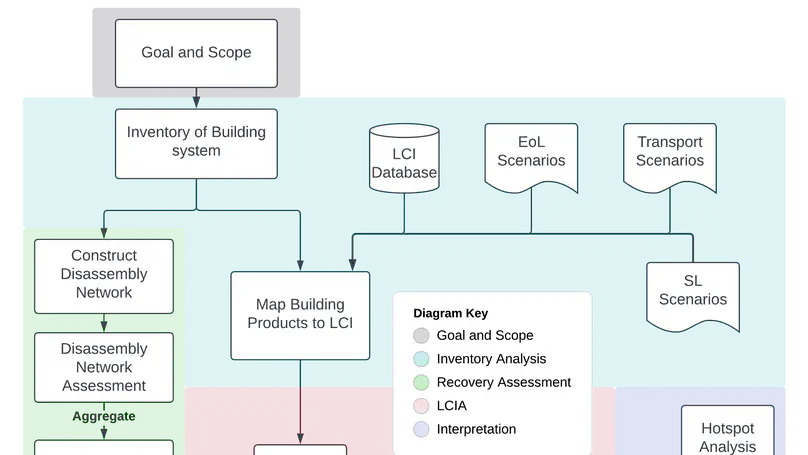

Existing life cycle assessment (LCA) methods for buildings often overlook the benefits of product recovery potential, whether for future reuse or repurposing. This oversight arises from the limited scope of such methods, which often ignore the complex interdependencies between building products. The present paper, backed by its supplementary Python library, introduces a method that addresses this gap, emphasizing the influence of product interdependencies and future recovery potential on environmental impact.

Methods

Implementing the proposed method requires adding a phase, the recovery potential assessment, to the four phases that constitute an LCA according to the ISO 14040/14044 guidelines. Given the disassembly sequence for each product, in the first step of the recovery potential assessment, a disassembly network (DN) is created that displays structural and accessibility dependencies. By calculating the average of the disassembly potential (DP) of each structural dependency (second step) associated with that product, we obtain the DP (0.1–1) at the product level in a third step. Because there is no empirical data available to support a specific relationship between product disassembly potential and recovery potential (RP) (0–1), we employ, in a fourth step, a flexible model specification to represent scenarios of how this relationship may look like. Ultimately, for each scenario, the resulting RP is used to enable a probabilistic material flow analysis with a binary outcome, whether to be recovered or not. The resulting product-level median material flows are then used to quantify the building’s environmental impact for a given impact category in the life cycle impact assessment (LCIA). The results are interpreted through an uncertainty, hotspot, and sensitivity analysis.

Results and discussion

Our results show that not considering the interdependencies between building products in building LCAs results in underestimating the embodied greenhouse gas (GHG) emissions by up to 28.29%. This discrepancy is primarily attributed to a failure to account for additional material flows stemming from secondary replacements owing to the interdependencies during the life cycle. When accounting for end-of-life recovery benefits, a zero-energy building (ZEB) design incorporating some DfD principles demonstrated up to 45.94% lower embodied GHG emissions than the ZEB design with low disassembly potential when assuming that recovered products will be reused.

Conclusions

Our approach provides first-of-a-kind evidence that not accounting for recovery potential may significantly distort the results of an LCA for buildings. The method and its supporting code support the semi-automated calculation of the otherwise neglected potential environmental impact, thus helping to drive the transition towards a more sustainable built environment. The supporting code allows researchers to build on the proposed framework if more data on the relationship between DP and RP become available in the future. Finally, while applied to buildings in this paper, the proposed framework is adaptable to any complex product with limited modifications in the supporting code.

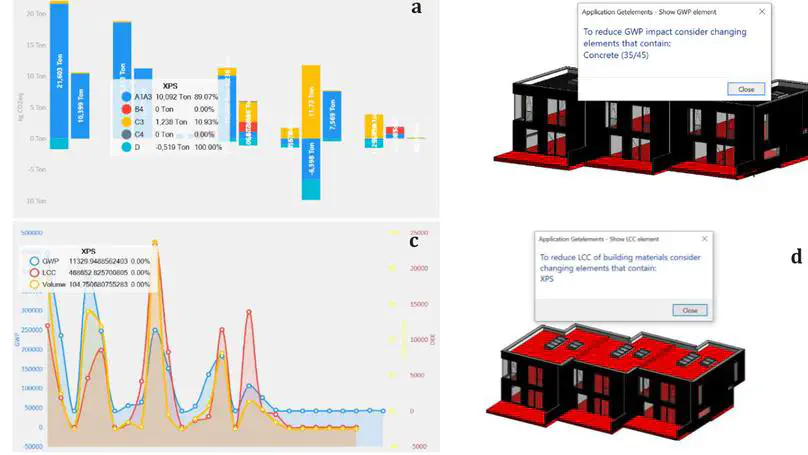

This paper is based on the Master’s thesis of Haitham Abu-Ghaida, which was supervised by Prof. Aliakbar Kamari. The paper was presented at the CIB W78 - LDAC 2021 conference. The paper proposes a bottom-up material mapping approach, ensuring fast and accurate mapping of the materials. A tool will be developed in collaboration with two Danish sustainability consultants in architecture and engineering, and is empirically evaluated on a large Danish housing project in Aarhus, Denmark.

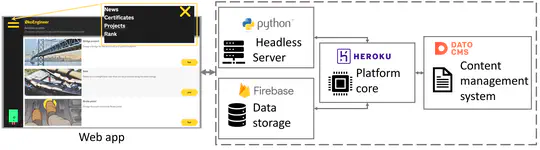

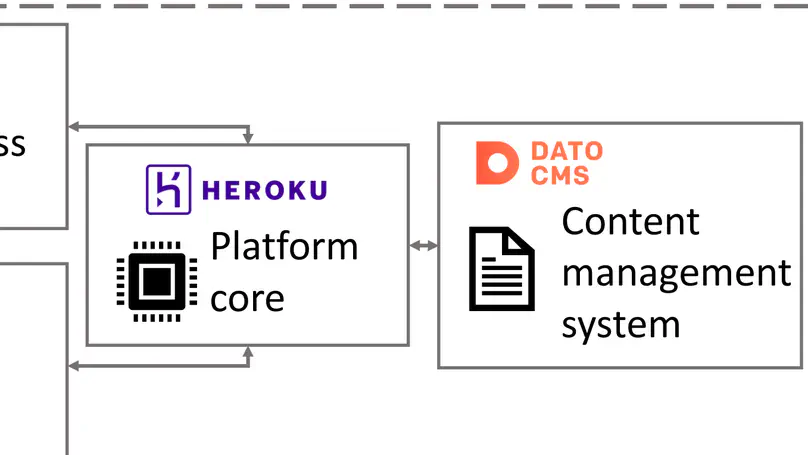

A growing body of academic research and educational institutions are recognizing the need to incorporate sustainability learning into fundamental engineering courses. Furthermore, the recent COVID-19 global pandemic has created a sudden need to augment traditional lecture-based teaching with effective web-based learning platforms. In light of these challenges the engineering education community needs to place a greater focus on designing and testing interactive, information technology-based tools for sustainability learning. To this end, our paper presents the design and implementation of Økoengineer - a web-based game platform that supports guided discovery-based learning of sustainability concepts in engineering curricula. Økoengineer is designed to familiarize engineering students with sustainability concepts and provide them with an understanding of how sustainability can be considered in the engineering design process. Therefore, Økoengineer hosts a collection of open-ended design tasks in multiple engineering disciplines. Students can solve these tasks iteratively and receive guidance through a combination of pre-recorded lectures on sustainability concepts and discussions with domain experts. Økoengineer also aims to increase students’ learning outcomes through the use of gamified elements, including high-score leaderboards, formative feedback & peer discussions, and rewarding achievements through virtual collectible badges. The Økoengineer platform is architected for scalability and allows course instructors to easily add new learning materials and design tasks.

Recent Publications

Recent & Upcoming Talks

Contact

Let’s connect.

- haitham.ghaida@uhasselt.be

- +32 488 07 12 93

- Agoralaan gebouw D 3590, Diepenbeek, Limburg 3500

- Outside the building there are temporary containers. (AB units) 112.

- Monday-Friday 9:00 to 17:00

- Book an appointment

- DM Me